Various

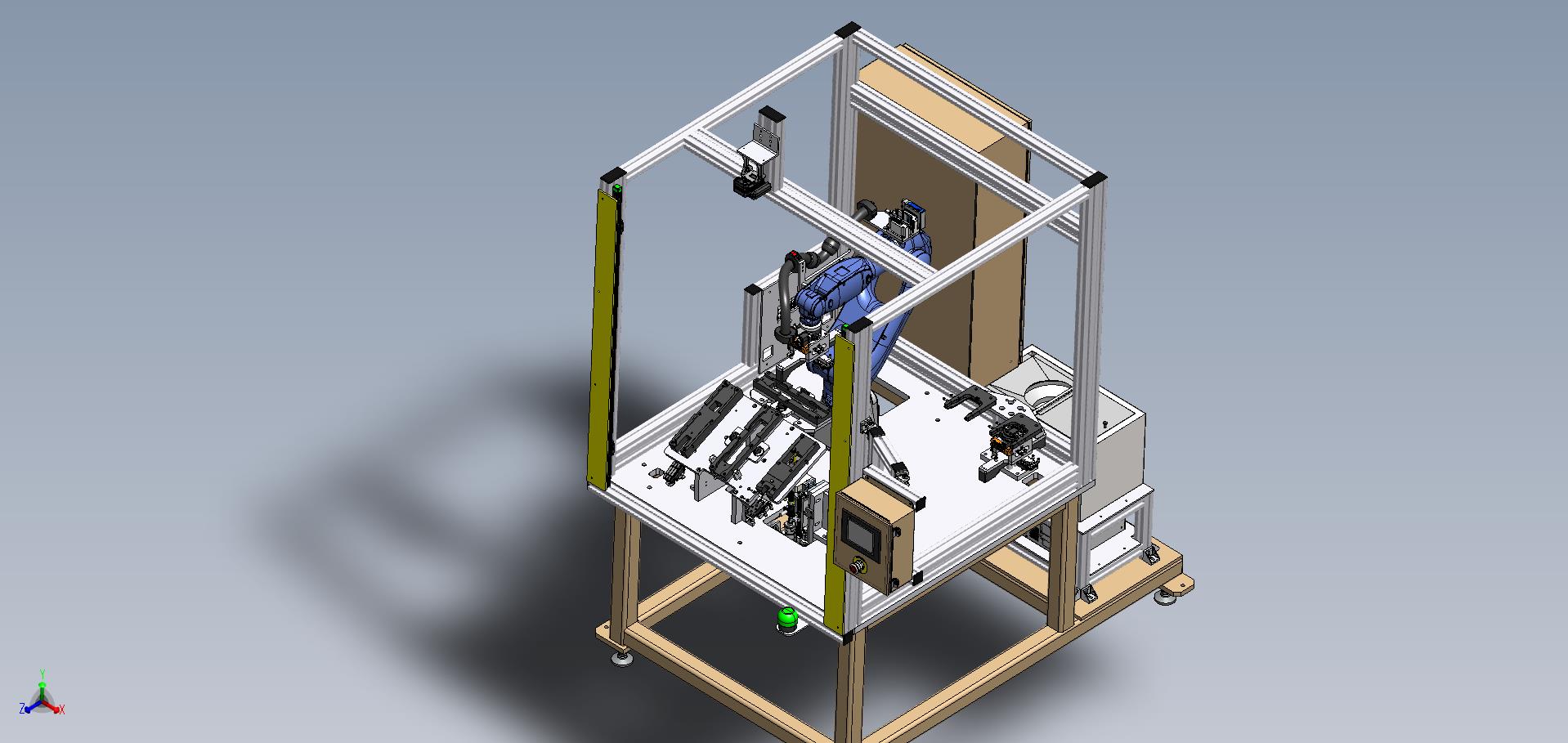

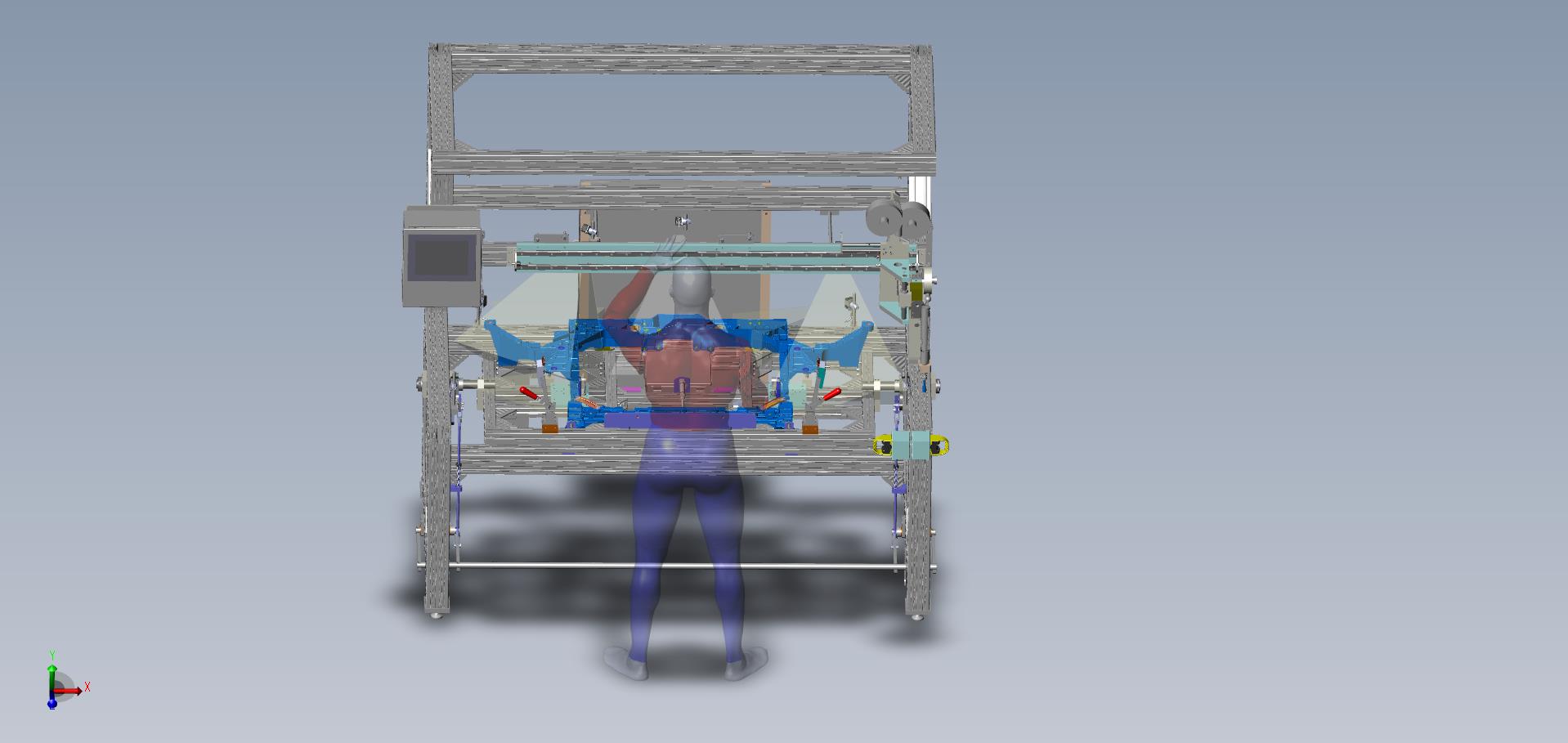

Assembly, Vision System, Inspection & Traceability

01 June 2024

$72,000 - $500,000

Do you have questions or need assistance with your Industry needs?

A Repeatable Approach Across Industries

Across automotive, general industrial, and high-mix manufacturing environments, Southern Tooling & Automation consistently designs modular automation cells as a foundational engineering principle — not a project-specific exception. This approach gives our customers equipment that remains productive as part designs, volumes, and technologies change over time.

Rather than building single-purpose machines, we develop flexible cell platforms that can be reconfigured, expanded, or upgraded without starting over.

What Modular Means in Practice

Across multiple projects, our automation cells are engineered to support:

This consistency allows customers to deploy automation that scales with their business rather than constraining it.

Competitive Advantage for Our Customers

Designing automation this way creates tangible advantages across industries:

Built for Change, Not Just Launch

Manufacturing environments rarely stay static. Programs evolve, part families expand, and new technologies become necessary. By treating modularity as a core design requirement, Southern Tooling & Automation delivers systems that remain valuable long after initial commissioning.

This philosophy is embedded across our automation projects — enabling customers to adapt, expand, and modernize without disruption.

We excel in sub-$4M automation systems but have the engineering and production capacity to deliver turnkey solutions up to $5.5M.

Yes — all critical fabrication, machining, assembly, and panel-building operations are performed in-house to ensure quality, speed, and full project control.

Absolutely; we design automation that seamlessly connects to upstream/downstream equipment and customer-preferred PLC platforms.

We engineer every system with robust components, clear diagnostics, and maintenance-friendly layouts to maximize uptime and simplify servicing.

Yes — our team handles full installation, on-site commissioning, and customized operator and maintenance training to ensure immediate operational success.

©2025 All Rights Reserved.